Reasons Why Semiconductor Reliability Testing is Essential

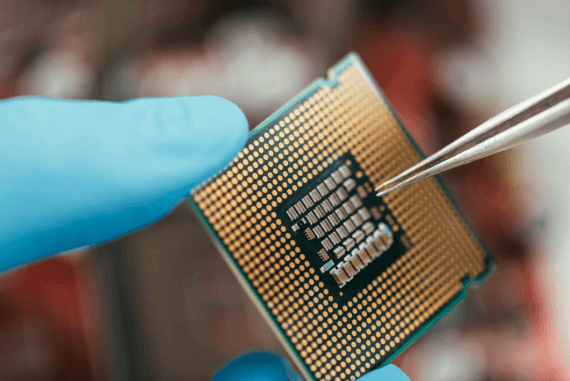

In today’s fast-paced and highly advanced society, the reliability of semiconductors is important for gadgets and networks like smartphones and electric vehicles. A single chip malfunction could have severe consequences, including product recalls, safety concerns, and damage to reputation. This highlights the importance of Semiconductor Reliability Testing – a necessary step to ensure products perform well in real-world situations. Effective testing not only protects products but also maintains the reputation of the brand and inspires confidence in technological progress.

Importance of Reliability Testing in the Semiconductor Industry

Ensuring the reliability of semiconductors is important as they must be able to withstand a range of conditions, including temperature fluctuations and voltage spikes. This is especially important in high-stakes industries like aerospace and medical devices, where even small failures can have serious repercussions. Therefore, it is imperative to identify any potential weaknesses early on.

As technology continues to advance, the need for improved performance and durability in devices grows among consumers. Reliability testing not only satisfies these rising demands but also fosters consumer confidence. Through prioritizing thorough testing, businesses can conserve resources, stay ahead in the market, and showcase a dedication to excellence and advancement within the semiconductor industry.

Impact of Failed Semiconductors on Devices and Systems

The impact of failed semiconductors can be devastating with consequences rippling across various sectors, from consumer electronics to essential infrastructure.

- Automotive Industry: In cars, malfunctioning semiconductors can compromise essential safety features such as airbags, anti-lock braking systems (ABS), and collision prevention systems. This can endanger lives, prompt costly recalls, and damage a brand’s reputation, affecting consumer trust.

- Consumer Electronics: Smartphones, computers, and other personal devices rely on semiconductors for smooth functionality. A chip failure can lead to system crashes, data loss, or performance glitches, causing user frustration and undermining brand loyalty.

- Critical Infrastructure: Power grids and communication networks depend heavily on the reliability of semiconductors. A failure in this context could result in widespread outages, economic disruption, and even public safety risks, highlighting the importance of high-quality, durable chips in these sectors.

- Business Continuity: Many industries rely on semiconductor-dependent technologies for day-to-day operations, including manufacturing, finance, and healthcare. A semiconductor failure could halt production lines, disrupt services, or lead to costly delays.

The reliability of semiconductors is critical to maintaining the smooth operation of not just individual devices but also entire industries and national infrastructure. This makes semiconductor quality and resilience a cornerstone of modern technology.

Types of Reliability Tests for Semiconductors

Semiconductor reliability testing is essential to ensure chips perform optimally under stress. Key tests include:

- Thermal Cycling: This test subjects semiconductors to extreme temperature fluctuations, simulating real-world conditions. It helps identify failures caused by material expansion and contraction, which can lead to cracks or delamination in the chip’s components.

- Electromigration Testing: This evaluates how electrical currents affect the movement of metal atoms in the semiconductor. It is critical for high-performance applications like processors, where metal lines can degrade over time due to high currents.

- Moisture Resistance Testing: This test assesses a chip’s ability to withstand moisture exposure, which can cause corrosion, short circuits, or material degradation. It’s important for semiconductors in environments with varying humidity, such as automotive and consumer electronics.

- Mechanical Stress Testing: This simulates physical stresses like bending, vibration, or pressure during assembly, transport, or use. It helps identify weaknesses that could lead to failure under strain.

These tests provide valuable insights that help manufacturers improve chip design, materials, and processes to ensure long-term reliability in diverse applications.

Benefits of Rigorous Semiconductor Reliability Testing

Semiconductor reliability testing is crucial for ensuring the success of both products and manufacturers. Its benefits include:

- Enhanced Longevity: Testing simulates real-world conditions to identify potential failures, ensuring longer-lasting semiconductors with consistent performance.

- Improved Performance: Reliable semiconductors reduce glitches, slowdowns, and crashes, enhancing overall device operation and user experience.

- Cost Savings: Early detection of flaws prevents costly post-release issues like recalls, repairs, and brand damage.

- Increased Consumer Confidence: Strong testing builds trust, leading to greater consumer investment in dependable products.

- Fostering Innovation: Reliable components allow designers to explore new technologies and applications confidently, driving progress in industries like AI, automotive, and electronics.

Semiconductor reliability testing is vital for producing high-quality, durable devices while fostering trust and innovation.

Challenges in Conducting Reliable Tests and How to Overcome Them

Conducting reliable semiconductor testing comes with several challenges, but these obstacles can be overcome with the right strategies. Here are the primary challenges and ways to address them:

1. Complexity of Semiconductor Materials and Designs

- Challenge: As semiconductors evolve, new materials and more complex designs make it difficult to develop reliable testing protocols.

- Solution: Collaboration among various fields is key in developing precise and effective testing techniques for new materials and complex designs. A multidisciplinary approach, involving engineers, material scientists, and reliability specialists, ensures thorough testing under realistic conditions.

2. Simulating Real-World Environmental Conditions

- Challenge: It’s difficult to replicate real-world conditions (e.g., temperature fluctuations, humidity, and mechanical stress) in a lab environment, leading to gaps in testing accuracy.

- Solution: Advanced simulation tools are key. These tools can model a wide range of environmental factors and operational scenarios, providing more accurate predictions of semiconductor performance in actual use cases. This bridges the gap between laboratory conditions and real-world environments, ensuring more reliable results.

3. Infrastructure and Expertise Requirements

- Challenge: The need for specialized equipment and expertise increases the cost and time required for thorough testing.

- Solution: Investing in cutting-edge infrastructure and continuous training for staff helps maintain high testing standards. This ensures that equipment and personnel are equipped to handle the complexities of modern semiconductor testing, improving testing precision and reliability.

To enhance the quality and durability of semiconductors, businesses can focus on fostering collaboration, utilizing advanced simulations, and investing in infrastructure. As a result, they can produce more dependable and high-functioning devices that meet the standards of the industry.

Read also: How Advanced Technology Impacts Lasik Cost in Toronto

Future Trends in Semiconductor Reliability Testing

Semiconductor reliability testing is advancing rapidly, with technologies like artificial intelligence (AI) and machine learning transforming testing processes. These innovations enable predictive analytics, allowing engineers to anticipate potential failures before they happen.

A key trend is the rise of Internet of Things (IoT) devices, which increase the demand for dependable semiconductors. Testing must evolve to accommodate the unique operating conditions and environments that IoT devices face.

Miniaturization of components presents both challenges and opportunities, requiring more precise testing methods to ensure performance under various stresses.

Sustainability is also gaining momentum in the industry, with a growing focus on environmentally friendly materials and practices to reduce waste and energy consumption during testing.

These developments point to a shift toward smarter, more efficient semiconductor reliability testing practices that meet the demands of a rapidly changing market.

Conclusion: Why We Cannot Ignore the Importance of Reliable Semiconductors

Semiconductors are fundamental to modern technology, and their performance has widespread implications across many sectors. Ensuring their reliability is crucial, as failures can lead to costly malfunctions and, in critical fields like aerospace and healthcare, even safety risks. As the demand for high-performance chips grows, semiconductor manufacturers must adopt stringent testing protocols to guarantee quality and durability.

Investing in reliability testing not only protects manufacturers from potential losses but also reinforces consumer confidence in electronic products. In an era of rapid technological advancements, prioritizing the reliability of semiconductors is vital to sustaining innovation and progress across industries. Without this focus, future advancements may face setbacks, hindering the development of next-generation technologies.