Industrial Cobots Applications for Modern Factories

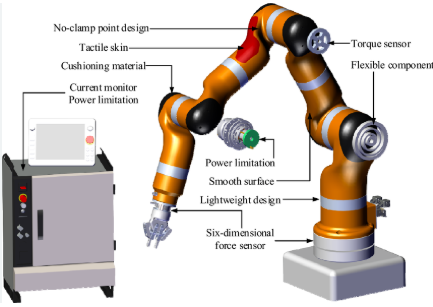

As factories evolve toward smarter and more connected operations, industrial cobots are becoming essential tools for modern manufacturing. Unlike traditional robots that require cages and strict supervision, cobots are designed to safely collaborate with human workers while enhancing speed, accuracy, and flexibility on the production floor.

From assembly lines to packaging and quality control, the applications of industrial cobots are expanding rapidly, helping factories meet growing demands while reducing costs and improving safety. In this article, we’ll explore the most impactful industrial cobots applications for modern factories and how they’re shaping the future of production.

Cobots in Assembly Lines

Cobots are key in modern assembly lines because they are flexible, safe, and efficient. They help by performing repetitive tasks, improving precision, and supporting workers.

Key Applications:

- Screwdriving and Fastening

Cobots perform repeated screwing and fastening with consistent force, which reduces mistakes, increases production speed, and ensures high-quality assembly.

- Part Insertion and Assembly

Cobots assist in placing small components, such as connectors or pins, into assemblies. They are ideal for production lines that change frequently because they can be quickly reprogrammed for different tasks.

- Kitting and Component Sorting

In industries like aerospace, cobots equipped with AI and cameras can pick, sort, and assemble component kits for workers. This automation reduces mistakes and speeds up production.

- Quality Inspection

Cobots with vision systems check products for defects in real-time, ensuring high quality and reducing the need for manual inspection.

Industry Examples

- Automotive Manufacturing: Cobots handle repetitive tasks like fastening components or checking alignment, which speeds up production and reduces the risk of errors or injuries for human workers.

- Electronics Assembly: Cobots help place tiny components on circuit boards and perform precise soldering. Their accuracy ensures that electronic devices meet high-quality standards, reducing defects and improving overall reliability.

- Consumer Goods Packaging: Cobots are used to sort, pack, and organize products efficiently. By automating repetitive packaging tasks, they increase throughput, maintain consistent quality, and reduce the physical strain on workers.

Cobots help assembly lines by doing repetitive tasks, working precisely, and keeping workers safe. They are easy to use and can be used in many manufacturing industries.

Cobots in Material Handling and Packaging

Cobots are helping industries handle and package materials more efficiently. They take over repetitive tasks, speed up work, and make workplaces safer.

Key Applications:

- Material Transport and Sorting

Cobots move raw materials, parts, and finished products between workstations, conveyors, and storage areas. They can load, unload, pick, and sort items, reducing manual work and lowering the risk of injuries.

- Palletizing and Depalletizing

Cobots stack and unstack products on pallets in a consistent way, speeding up the process and optimizing storage space.

- Packaging and Case Loading

Cobots handle tasks like placing products into cartons, sealing boxes, and labeling, improving speed and consistency while reducing physical strain on workers.

- Quality Inspection

Cobots equipped with cameras inspect products in real-time, detecting defects, maintaining high-quality standards, and reducing the need for manual inspections.

Cobots are transforming material handling and packaging by automating repetitive tasks, boosting efficiency, and improving safety. Their flexibility and ease of integration make them valuable in industries like manufacturing, logistics, and food processing.

Cobots in Quality Inspection and Testing

Cobots automate repetitive inspection and testing tasks, increase precision, and help ensure products meet high-quality standards.

Key Applications:

- Visual Inspection

Cobots equipped with 2D or 3D cameras can detect defects such as scratches, misalignments, or surface imperfections, catching even small flaws that human inspectors might overlook.

- Dimensional and Geometric Measurement

Cobots can measure the size and shape of parts to make sure they meet exact standards. This is very important in industries like car and airplane manufacturing.

- Functional Testing

Cobots can test switches, buttons, and electronic components to ensure they work correctly, simulating real-world use before products reach customers.

- AI and Machine Learning Integration

Advanced cobots use AI to enhance inspections. For example, AI-powered robots at Toyota combine machine intelligence with human oversight to verify parts and maintain quality control.

Cobots are revolutionizing quality inspection and testing by making processes faster, more accurate, and more consistent. They improve product quality and support smarter, more automated manufacturing.

Cobots in Welding and Fabrication

Cobots enhance welding and fabrication by automating repetitive tasks, increasing accuracy, and improving workplace safety.

Key Applications:

- Arc Welding (MIG, TIG, Stick)

Cobots can perform different types of arc welding with consistent quality and efficiency, reducing labor costs. They are flexible, quick to set up, and can be customized to meet business needs.

- Laser and Plasma Welding

Cobots can also handle laser and plasma welding, providing high precision for industries that need fine tolerances and minimal heat damage.

- Spot Welding

Used in automotive and heavy machinery, cobots perform spot welding with uniformity and strength, reducing human error and improving product quality.

- Welding Support Tasks

Cobots assist with positioning parts, holding fixtures, and inspecting welds, freeing skilled welders to focus on complex work and improving workflow efficiency.

Cobots make welding and fabrication easier and safer by doing repetitive tasks, working more accurately, and protecting workers. They are very useful in industries like automotive, aerospace, and heavy machinery.

Benefits Across Applications

Cobots help businesses work safer, smarter, and more efficiently in manufacturing.

- Safer Workplaces

Cobots work safely alongside humans. With sensors and force-limiting features, they stop when they detect human presence, reducing accidents.

- Easy to Use and Flexible

Cobots are small, simple to operate, and easy to program. They can be quickly set up for different tasks and moved to various workstations, making them adaptable to changing production needs.

- Cost-Effective

Cobots are cheaper to set up and operate than traditional industrial robots. Automating repetitive tasks increases productivity and reduces labor costs.

- High Quality and Consistency

Cobots execute tasks with precision and repeatability, ensuring each product meets strict standards. This reduces mistakes, minimizes rework, and maintains consistent quality across production runs.

- Support Human Workers

Cobots take on repetitive or physically demanding tasks, freeing employees to focus on more complex or creative work and helping them develop new skills.

Cobots improve safety, efficiency, and quality across multiple sectors. Their flexibility and ease of integration make them valuable tools in modern manufacturing.

Conclusion: Industrial Cobots

Industrial cobots are reshaping modern factories by combining safety, efficiency, and precision in a wide range of applications. From assembly lines and material handling to quality inspection, testing, welding, and fabrication, cobots automate repetitive or physically demanding tasks while supporting human workers. This not only reduces errors and production costs but also enhances workplace safety and allows employees to focus on more complex, value-added work.

Their flexibility, ease of programming, and ability to work alongside humans without cages make cobots ideal for dynamic and evolving production environments. By integrating cobots, factories can boost productivity, maintain consistent quality, and stay competitive in today’s fast-paced manufacturing landscape. In short, industrial cobots are essential tools for building smarter, safer, and more efficient factories.